Feb 7, 2019 | Product review, Swimming Pool Covers

How do you choose a good swimming pool cover? Here is some information to help you choose. Heat is lost from a swimming pool by evaporation of the water surface, if you cover the water surface you will cut heat losses. A simple plastic sheet would do the job but it...

Sep 21, 2017 | Product review, swiming pool enclosures

At PoolStore our product knowledge and expertise is second to none. We will not list a product unless we know exactly how it works and what it it does. But in the case of our swimming pool enclosures we cannot exactly take one out of the box and put it in our pool. So...

Apr 26, 2013 | Pool Science, Swimming Pool Covers

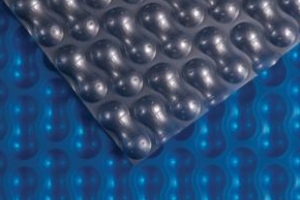

We are often asked why has my swimming pool’s bubble cover started to degrade? The usual pattern is that you find little bits of white plastic floating in your pool water. You wonder where they have come from and eventually find that they are from the underside...

Mar 1, 2012 | Product review, Swimming Pool Covers

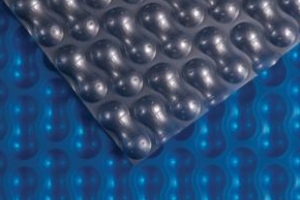

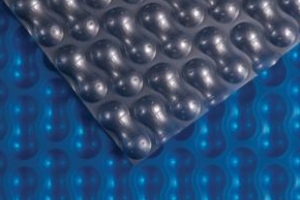

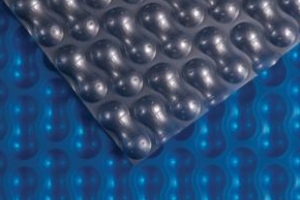

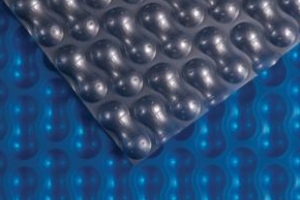

Up until now there had only been one fundamental type of summer pool cover available now, for the first time, pool owners can choose between two types. Swimming pool summer covers are often called “bubble covers” because they look very much like a sheet of...

May 27, 2010 | Fun, Swimming Pool Covers

Swimming Pool Safety Covers are not just for keeping your children and pets out of your swimming pool. You never know when a stray animal might wander in to your pool! This pregnant donkey was very lucky because the pool was empty. Had she fallen in when the pool was...